REILHOFER KG, headquartered in Karlsfeld near Munich in Germany, operates in the area of acoustic early damage detection and end-of-line quality assurance since more than 25 years. The diagnostics systems are used throughout various stages of development, from component testing, testing of single engines and transmissions to testing the entire powertrain and in test benches of the production as well.

The delta-ANALYSER is a measuring system, which is used for early stage damage detection of acoustic noise emitting machines such as transmissions, engines, shafts and turbines under dynamic conditions.

It detects failure-related changes of the machine by comparison of the current vibration behavior to a previously built reference. The delta-ANALYSER can be compared to a master craftsman, who recognizes the state of his machines by their noise.

The eol-ANALYSER (end-of-line ANALYSER) has been specially designed for the final test of transmissions and engines in the automotive industry.

Special emphasis has been put on easy operation and self-learning, floating limits.

All failures are classified through the integrated pattern recognition and associated with the correct component.

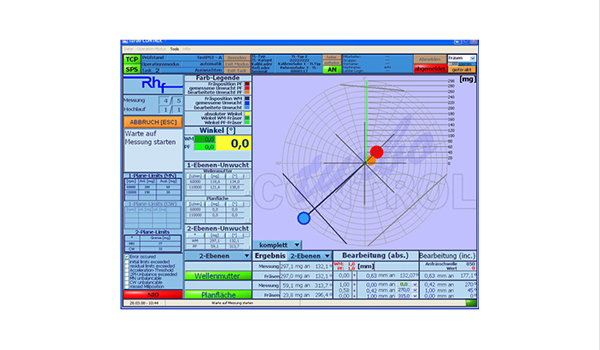

The turbo-CONTROL measuring system has been designed for functional tests and the 2-plane balancing of exhaust turbochargers of any type and size. The ever-increasing requirements with regard to characteristics, quality, stableness, price and acoustics demand for a fully automated test and balancing process.